OUR COMPANY SPECIALIZED IN PRODUCTION OF ALL TYPES SLEEVE , BUSH IN THE LINES USE IN METAL PLATING TANK , IN CHEMICALS TANK, SEA WATER PUMPING

- REQUIREMENT

Environment: In metal plating tank, in chemicals tank, sea water

Operating temperature: ≥650 ° C

Feature requirements: Corrosion resistance, Abrasion resistance, High toughness

Thermal Spray, Weld material: Inconel, C5IC, T800, OF94IC (in-house developed material) Stellite # 6, # 12…

The sink roll placed immersed in the molten metal does not have a driving device, and the shaft of the roll rotates while being in contact with the bearing. Therefore, since the sleeve and bush material on the roll shaft receive sliding resistance from the bearing in the molten metal, performance such as corrosion resistance, wear resistance, and high toughness against the molten metal is required for long-term use. Therefore, we have been studying various sleeves and bushing materials with roll shafts placed in the molten metal plating bath.

- EXEMPLE

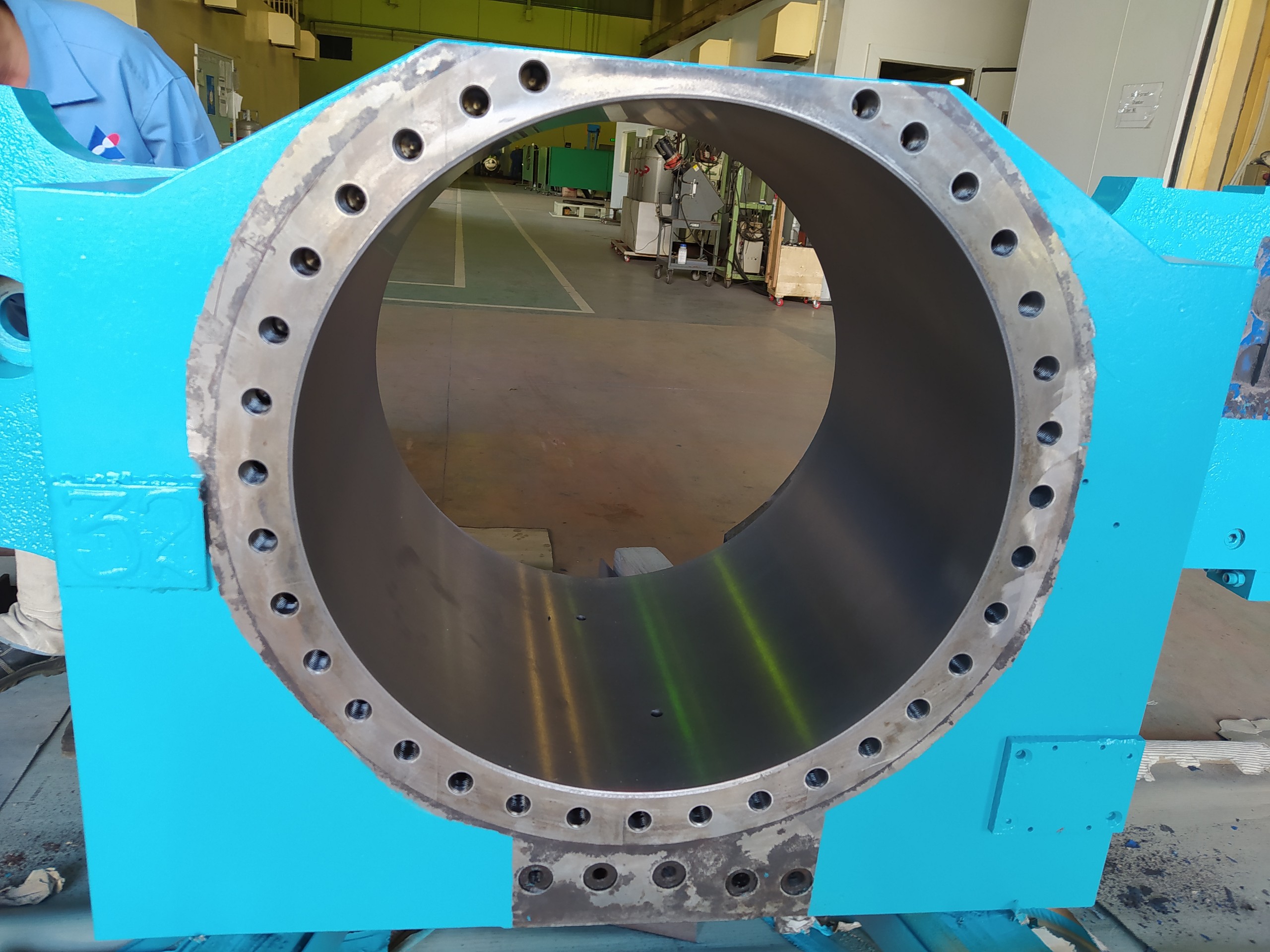

On the outer of the sleeve base material (SUS316L steel), a cobalt-based alloy (stellite alloy) is used as a welding material, and overlay welding is performed by the PTA method. The overlay welding (circumferential direction) was carried out while gradually shifting in the roll axis direction so that the entire surface was constructed. Subsequently, overlay welding is performed on the outer in the roll axis direction using tungsten carbide particles as a welding material, and a second overlay weld layer having a thickness of 2 mm is formed on the surface of the first overlay weld layer.

With this product, the service life is nearly 3 times longer than that of conventional sleeve,bush.