- CHOCK

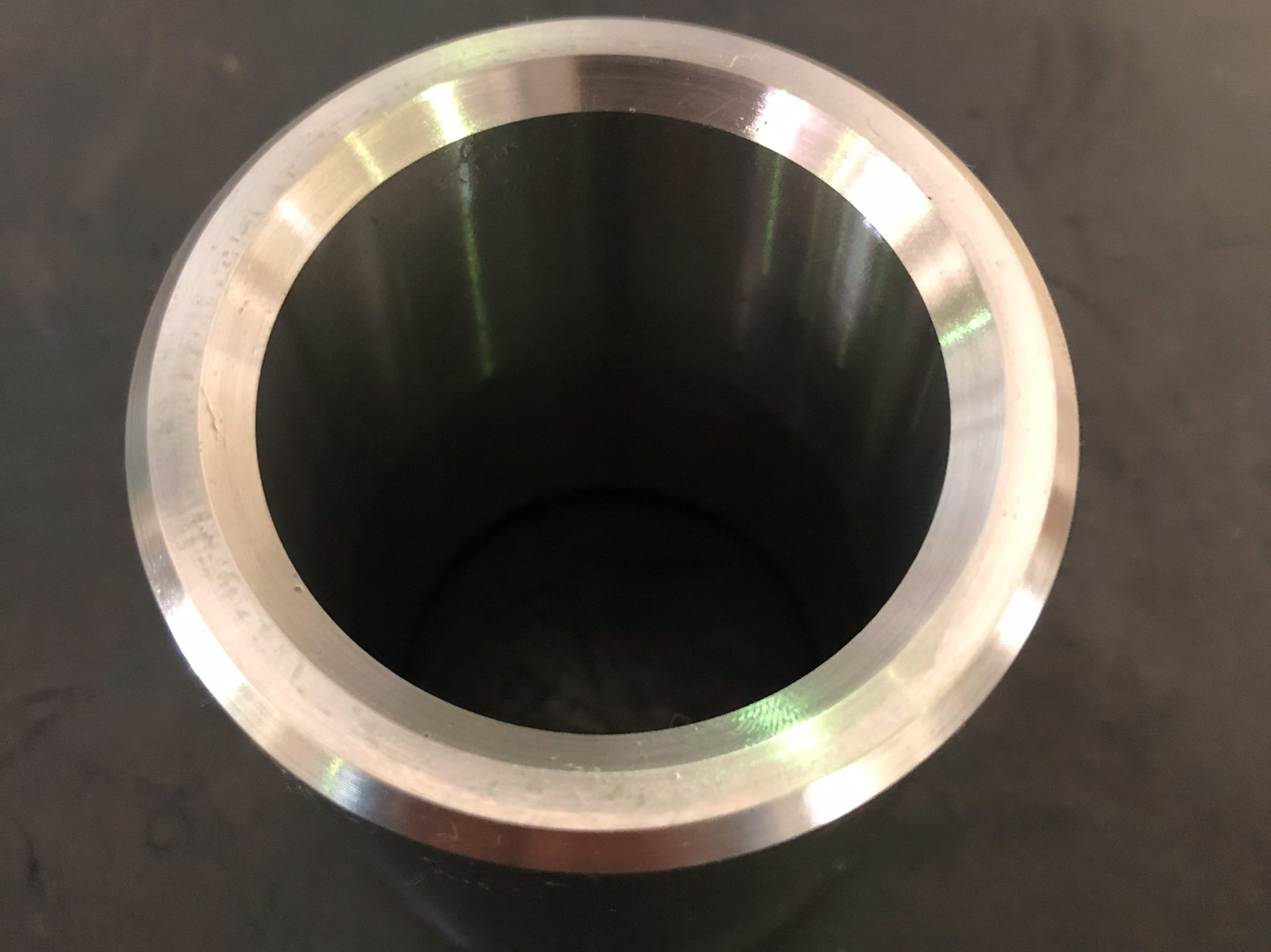

Introducing an example of repairing bearing box (chock) that supports a drive unit such as a roll by thermal spraying.

Since the inner diameter of the bearing box (chock) was tuck, it was scorched and the surface was uneven. If you operate with unevenness, the operation accuracy will drop, so we considered a method to adjust the inner diameter.

Initially, we considered making a new product, but found that repairing the actual product would shorten the delivery time, so we decided to repair the inner diameter of the bearing box (chock) by thermal spraying.

There are various repair methods such as welding, thermal spraying, and plating.

Since the bearing box (chock) to be repaired this time is thin, it is predicted that distortion will occur if heat is applied by welding, so it was decided to adopt the thermal spraying method (construction temperature 100 ° C or less) for repair.

We also repaired the liner surface of the bearing box (chock) by welding and spraying to restore the original dimensions.

- THERMAL SPRAY REPAIR MERIT

+ It can be repaired repeatedly to completely protect the base material.

+ Due to low temperature processing, distortion does not occur and there is no change in the metallographic structure of the base metal itself.

+ Construction time is shortened.